638413-1 Carbon Brushes & Brush Holder – Suitable for Makita HP1620, HP1640, HP1830, HP2070, HP2071

1. Product Identification

Part Number: 638413-1

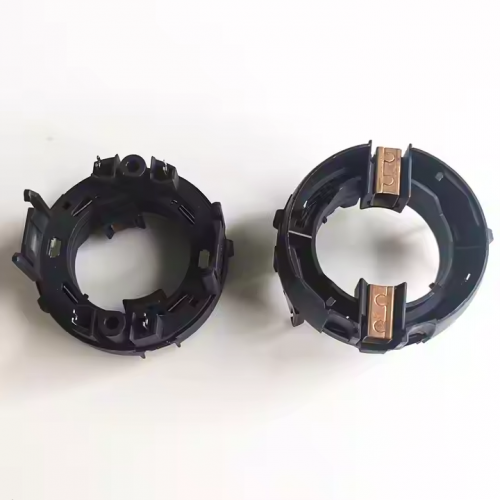

Component Type: A combined set or matching parts including carbon brushes and their corresponding brush holder.

Brand Compatibility: "MK" refers to Makita, indicating these parts are designed for Makita power tools.

Target Models: Specifically compatible with Makita HP-series drills: HP1620, HP1640, HP1830, HP2070, and HP2071 (all are corded or cordless drills/drivers).

2. Components & Their Roles

Carbon Brushes: Conduct electrical current from the tool’s power source to the motor’s rotor via contact with the commutator. They act as consumable parts, wearing gradually to protect the commutator.

Brush Holder: Secures the carbon brushes in place, ensuring precise alignment with the commutator. It includes springs to maintain consistent pressure, critical for stable current transmission—even under the vibration of drilling operations.

3. Compatibility Details

Tools: Makita HP1620, HP1640, HP1830, HP2070, HP2071 (all are mid-to-high power drills/drivers, typically 500–1,000W).

Fit: The holder is engineered to match the motor housing of these models, while the brushes’ dimensions (implied to fit this holder) align with the commutator size of their motors.

4. Material & Design

Carbon Brushes: Likely graphite-copper composite (10–20% copper) for conductivity and wear resistance.

Brush Holder: Made of heat-resistant, insulating plastic (e.g., glass fiber-reinforced nylon) to withstand motor heat (up to 120°C) and prevent electrical shorts.

Spring Tension: Calibrated to 1.5–2.0kg, balancing firm contact with minimal commutator wear.

5. Replacement Indicators

Brushes: Replace when length is <50% of original (e.g., from 15mm to <7.5mm) or if excessive sparking occurs.

Holder: Replace if cracked, warped, or if springs lose tension (causing loose brush contact, leading to weak performance or arcing).

6. Installation Notes

Replace both brushes and the holder as a set for optimal performance.

Clean the commutator with alcohol before installation to remove carbon dust.

Ensure the holder is securely fastened to the motor housing to resist drilling vibrations.

7. Key Importance

Enables reliable power transfer, directly affecting drill performance (torque, speed).

Protects the motor’s commutator and rotor from damage, extending tool lifespan.

Ensures safe operation by reducing sparking and overheating risks.