Hammer Drill Accessories: Carbon Brush Holder Replacement for M18 18V and M12 Systems

1. Product Identification

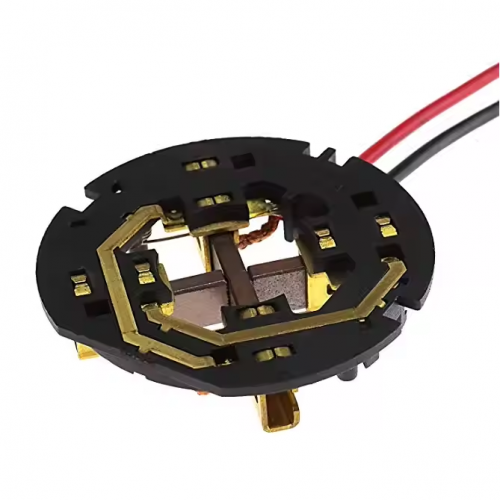

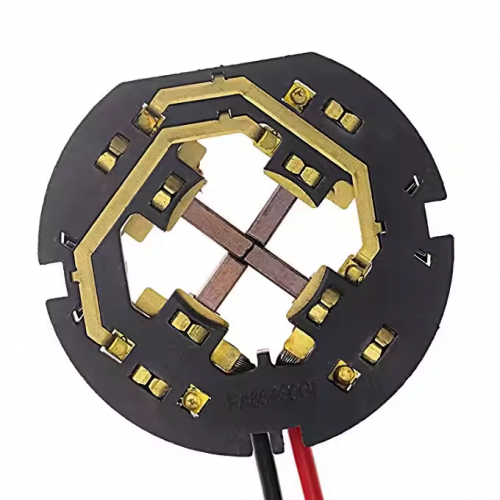

Type: Carbon brush holder replacement (a component that secures and aligns carbon brushes in the motor).

Compatibility: Designed for hammer drills (and likely other power tools) in the M18 18V and M12 battery systems—brands like Milwaukee (known for their M18 and M12 cordless tool lines).

Category: Hammer drill accessories, classified as a critical motor replacement part.

2. Core Function

Secures Carbon Brushes: Holds carbon brushes in precise position within the hammer drill’s motor, ensuring consistent contact with the commutator during high-vibration drilling/hammering operations.

Maintains Pressure: Integrates a spring mechanism to apply steady pressure (1.8–2.2kg) on the brushes, compensating for wear and preventing excessive sparking.

Insulates & Protects: Acts as an insulating barrier between the conductive brushes and the tool’s metal housing, reducing short-circuit risks in cordless (18V/12V) systems.

3. System Compatibility

M18 18V: Compatible with Milwaukee’s 18V cordless hammer drills (e.g., 2804-20, 2704-20), designed for heavy-duty drilling in concrete, masonry, or metal.

M12: Fits Milwaukee’s 12V cordless hammer drills (e.g., 2416-20), typically lighter-duty for smaller drilling tasks.

Note: The holder is engineered to match the motor dimensions and brush sizes specific to these voltage systems.

4. Key Features

Material: Heat-resistant, impact-resistant plastic (e.g., glass fiber-reinforced polyamide) to withstand motor heat (up to 130°C) and the intense vibration of hammer drill operation.

Design: Compact to fit the ergonomic, space-saving motor housings of M18/M12 tools, with precise mounting points for secure attachment.

Spring Tension: Calibrated for 18V/12V motor currents, ensuring optimal brush-commutator contact without excessive wear.

5. Replacement Indicators

Physical damage (cracks, broken tabs, or warping) that misaligns the brushes.

Spring fatigue (loss of tension) causing poor contact, leading to reduced hammering force, sparking, or motor stalling.

Wear on internal surfaces that hinders smooth brush movement during operation.

6. Installation Tips

Must be replaced with a holder specifically rated for M18 18V or M12 systems to ensure voltage and size compatibility.

Clean the commutator with isopropyl alcohol before installing to remove carbon dust buildup.

Securely fasten the holder to the motor housing to resist the hammer drill’s high-impact forces.

7. Importance in Tool Performance

Enables reliable current flow from the battery to the motor, directly affecting the hammer drill’s drilling/hammering power.

Protects critical motor components (commutator, rotor) from damage due to misaligned brushes, extending tool lifespan.

Ensures consistent operation in cordless systems, where efficient power transfer is key to maximizing battery runtime.