Computations and Assumptions in Drone Design

Before commencing the design of a new drone, the primary task is to define its core attributes and functional positioning—such as establishing a specific takeoff weight range, determining rotor configurations, and planning target endurance parameters. From an engineering perspective, the drone development process typically advances through a “design cycle” model, characterized by the iterative nature of the design process. When building the initial prototype, work proceeds based on a series of initial assumptions. However, as component selections are finalized and various design elements are integrated and coordinated, most of these initial assumptions require adjustment and refinement based on actual circumstances.

In this article, we will cover:

1. Finding the right battery to extend flight time.

2. How to select drone motors and propellers (with database)?

3. Replacing components to maximize efficiency.

4. How to select an ESC?

5. How to calculate drone flight time?

The design cycle begins when designers examine how the first version of their design differs from assumptions, then return to the starting point with new insights (Figure 1).

Figure 1: Schematic of the Drone Design Cycle

We begin the design process assuming our drone weighs 777g and is capable of autonomous flight. Based on these assumptions, we predict each propeller requires 1.9N of thrust for hover flight. Therefore, we seek the most efficient motor-propeller combination at 1.9N. Once we identify the most efficient combination, we gain the tools needed to estimate our flight time—which is where we start today.

For this article, we will refine our understanding of component weights. We assume the mass distribution of our 777g drone is as follows:

Motors (4): 148g

Propellers (4): 13.5g

Battery (1): 155g

Other components (camera, frame, ESCs, etc.): 460.5g

1. Flight Time

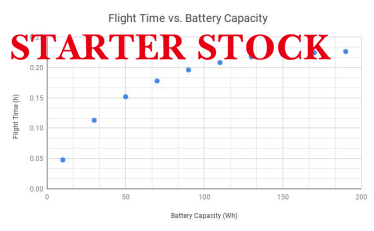

Our goal is to maximize the drone's flight time, enabling it to hover for as long as possible. In our previous article, we simulated flight times for drones with different battery capacities (Figure 2).

Figure 2: (Flight Time vs. Battery Capacity for Original Drone Design)

We assume our design will incorporate a Turnigy Nanotech 1300mAh 4S battery, including its mass in our overall calculations. The battery's capacity slightly exceeds 19.2Wh (14.8V × 1.3Ah = 19.2Wh), which occurs during the growth phase of the chart, yielding only approximately 4.5 minutes of flight time. Increasing battery capacity extends flight time, but at the cost of added weight. This marks the start of the design iteration cycle, where we swap components to build the drone that best meets our needs.

2. Selecting New Batteries for Maximum Flight Time

Flight time increases with battery capacity up to the 0.2-hour mark, but marginal gains become less significant beyond approximately 100-125Wh. For this reason, we will first replace the old battery with a new one around 100-125Wh capacity to increase our flight time. The Turnigy 5000mAh 6S LiPo battery pack fits our criteria well, with a capacity of 111Wh (Figure 3).

Figure 3 Turnigy 5000mAh/111Wh LiPo Battery (Photo: HobbyKing)

Turnigy 5000mAh/111Wh LiPo Battery (Photo: HobbyKing)

Compared to the old battery weighing just 155g, this new battery tips the scales at 655g. Assuming all other components remain unchanged at 622g, our drone's total mass now stands at 1277g. Therefore, we require at least 12.5N of thrust (1.277kg * 9.81) for drone hovering, equating to just over 3.1N per propeller. We also aim for at least double the thrust for better control, so we'll seek the most efficient propeller at 3.1N that can deliver up to 6.2N of thrust.

Recap: Our shortlist includes three propellers:

1. 6030R Gemfan => Diameter: 6“, Pitch: 3”, Mass: 2.22g

2. 6040R King Kong => Diameter: 6“, Pitch: 4”, Mass: 3.38g

3. 5030R Gemfan => Diameter: 5“, Pitch: 4”, Mass: 3.00g

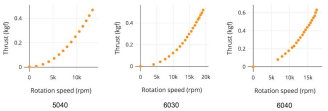

For our candidates, database data indicates all three propellers achieve 3.1N of hovering thrust, but only the 6040R King Kong approaches the maximum thrust of 6.2N (0.63 kgf) (Figure 4).

Figure 4: Pull Performance of Propeller Candidates

These results indicate that either our battery is too heavy or our motor/propeller combination is not generating sufficient pull. Since our goal is to maximize flight time, rather than immediately seeking smaller batteries, we will explore additional propellers that fit our frame constraints while producing greater pull.

3. Selecting New Propellers and Motors

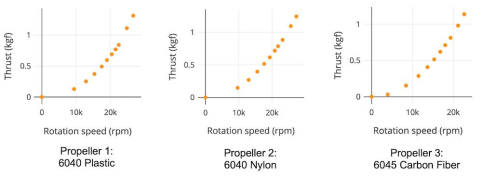

Our frame limits us to propellers with a diameter of 6 inches or smaller, but we can still experiment with pitch, material, and brand. We will use the drone component database to filter for propellers with a 6-inch diameter that generate at least 6.2N (0.63 kgf) of force. This search yields several promising options, but for simplicity, we narrow it down to the three candidates producing the highest thrust:

1. Propeller 1 → Diameter: 6“, Pitch: 4”, Mass: 3.38g, Material: Plastic

2. Propeller 2 → Diameter: 6“, Pitch: 4”, Mass: 4.32g, Material: Nylon

3. Propeller 3 → Diameter: 6“, Pitch: 4.5”, Mass: 6.78g, Material: Carbon Fiber (CF)

Figure 5: Pull Force vs. RPM for New Propeller Candidates

As shown in Figure 5, all our propeller candidates can generate a pull force of 10N (1kgf) or greater. For this reason, we can target a hovering pull force of 5N and a maximum pull force of 10N, enabling us to lift larger batteries using the same propulsion system.

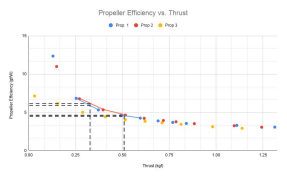

As shown in Figure 6, Propeller 1 and Propeller 2 exhibit very similar efficiencies at our initial 3.1N (0.32kgf) hover thrust and the new 5.0N (0.51kgf) hover thrust, differing by only about 0.1gf/W. Propeller 2 exhibits slightly higher efficiency but is also heavier. This increased weight may result in shorter flight times and leave less mass available for the battery. In a quadcopter configuration, the total difference amounts to 3.76g ((4.32g - 3.38g) * 4).

Figure 6 (Propeller Efficiency vs. Pull Force for New Propeller Candidates)

After a quick scan of online marketplaces, it became clear that 4g makes no difference in battery capacity at this size. For this reason, and since the impact of 4g weight on our drone is negligible, using Propeller 2 makes sense due to its higher efficiency.

Our next step will be identifying the most efficient brushless motor under our new 5N hovering pull test. Generally, we seek a motor capable of exceeding 10N maximum pull without being excessively large. We don't want the motor running at maximum speed for extended periods, nor do we want to haul a motor generating more pull and torque than necessary.

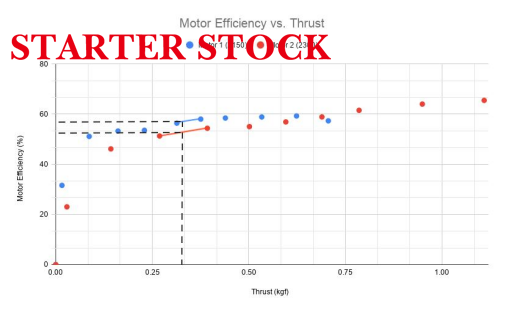

Among the two motors we previously tested—the MultiStar Elite 2306 2150Kv and the EMAX RSII 2207 2300Kv—only the 2300Kv motor met our maximum pull requirement (Figure 7). Therefore, we will need to consult the motor database to identify new candidates.

Figure 7 (Motor Efficiency vs. Pull Force for 2150Kv and 2300Kv Candidate Motors)

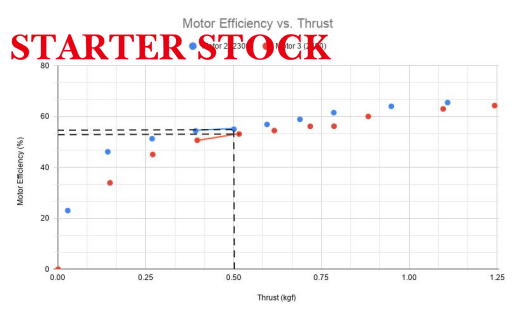

From the database, we identified the Hypetrain Blaster 2207 2450Kv as meeting our criteria. We tested each of the two motors paired with Propeller 2, with results shown in Figure 8. Motor 2, the EMAX RSII 2207 2300Kv, proved more efficient at our hovering workpoint of 5N (0.51kgf) and also delivered higher efficiency at our maximum pull of 10N (1.02kgf). The efficiency difference at the hover pull was approximately 2.2% (55.6% vs. 53.4%), but the 2300Kv motor was also lighter (32.37g vs. 36.96g), making our decision straightforward.

Figure 8 (Motor Efficiency vs. Pull Force for 2300Kv and 2450Kv Candidate Motors)

4. Selecting New Batteries for Maximum Flight Time in Our New Design

This is an opportune moment to summarize our component weights, as both our propeller and motor weights, along with our hover pull force, have changed. Here is the new breakdown:

Motors (4): 129.5g

Propellers (4): 17.3g

Other Components (camera, frame, ESC, etc.): 460.5g

Front Battery Mass: 607.3g

Maximum Mass: ~2000g

Based on these new values, our available battery mass is 1392.7g.

Since we've also selected motors and propellers, we can determine our discharge (C-rating) requirements—another factor in battery selection. We want to ensure our motors don't draw more current than the battery can supply, otherwise the battery may degrade rapidly or overheat. The formula for calculating battery current draw is: Current (A) = C-rating × Capacity (Ah).

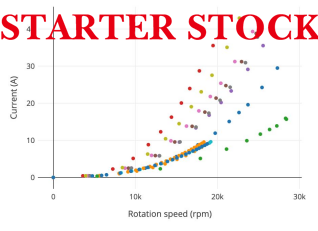

No continuous or surge current data is available online for the EMAX RSII 2207 2300Kv motor, but we can examine data from the RCbenchmark database and compare all tests completed using this motor. As shown in Figure 9, the maximum current achieved across various tests is approximately 42A.

Figure 9 Current vs. RPM of EMAX RSII 2207 2300Kv Motor

The Turnigy high-capacity 16000mAh 4S 12C Lipo Pack offers the highest Wh capacity among all batteries within our weight range, providing 4*3.7*16=236.8Wh. Weighing 1366g with a 12C discharge rating and 16Ah capacity, it can handle 192A current draw—exceeding our requirements.

5. ESC Selection

The primary consideration for ESC selection is its ability to deliver the motor's peak current. In our example, we don't want our motors to exceed 42A, so an ESC like the HobbyKing 60A ESC with 4A SBEC would work well. It can deliver up to 60A continuous current and up to 80A peak current while providing 4A current to the BEC. This gives us a bit of safety margin, making this ESC a solid choice for our drone.

图10 HobbyKing 60A ESC 4A SBEC

6. Calculating Our Flight Time

As we learned in the previous article, flight time depends on battery capacity and the power consumed by the propulsion system. Therefore, many factors come into play, summarized in the formula below.

E = Capacity; σ = Energy Density; M = Mass in grams (g)

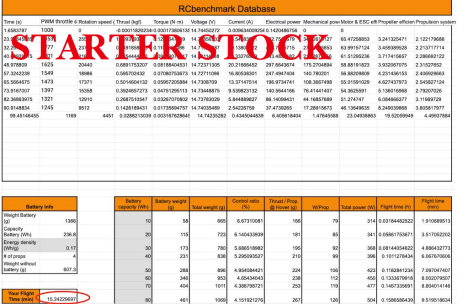

We can copy and paste our propulsion test data into this convenient flight time calculator. By inputting our weight and battery capacity, it provides the best estimated flight time based on our data. Our projected flight time is 15.2 minutes (Figure 11), a significant improvement over our initial design (which only allowed for approximately 4.5 minutes of flight time).

Figure 11 (Estimating our drone's flight time using a flight time calculator)

Conclusion

As we have seen, the drone design process is cyclical, and there is almost always room for design improvement. Collecting propulsion data is one of the best ways to identify areas for drone enhancement, and we provide numerous test benches and tools to help you achieve this.