-

98

-

2025-09-03 17:08:28

I. The Role of the Air Flow Meter Sensor and the Effects of Pollution

The Air Flow Meter (MAF Sensor) is a core component of the engine's electronic control system and is used to measure the amount of air that enters the engine, which directly affects the amount of fuel injected and ignition timing. According to statistics, about 30% of the engine power shortage or idle shaking problems are related to MAF sensor pollution (Source: Bosch Automotive Technology Manual). Common contaminants include:1. oil: from oil vapor or air filter failure

2. Dust: Particle adhesion due to untimely replacement of the air filter

3. Carbon deposits: formed by long-term low-temperature and short-distance driving.

2.The detailed cleaning methods and steps

(a) non-disassembly quick cleaning method (suitable for light pollution)1. Preparation tools: special electronic components cleaning agent (such as CRC MAF Cleaner), soft brush

2. Operation process:

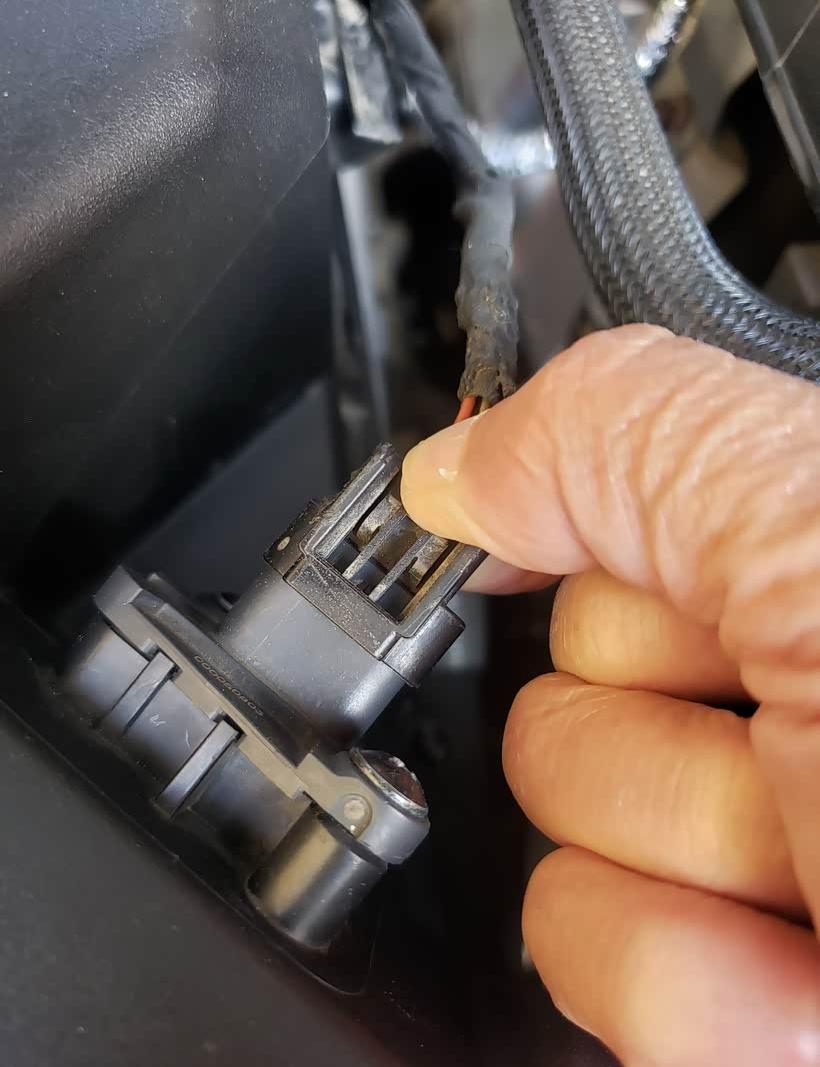

- Disconnect the sensor plug

- Spray the cleaner at a distance of 20cm from the sensitive components (for 2-3 seconds).

- Natural air drying 15 minutes (not compressed air)

(b) Deep disassembly and cleaning method (for serious contamination)

1. Disassembly points:

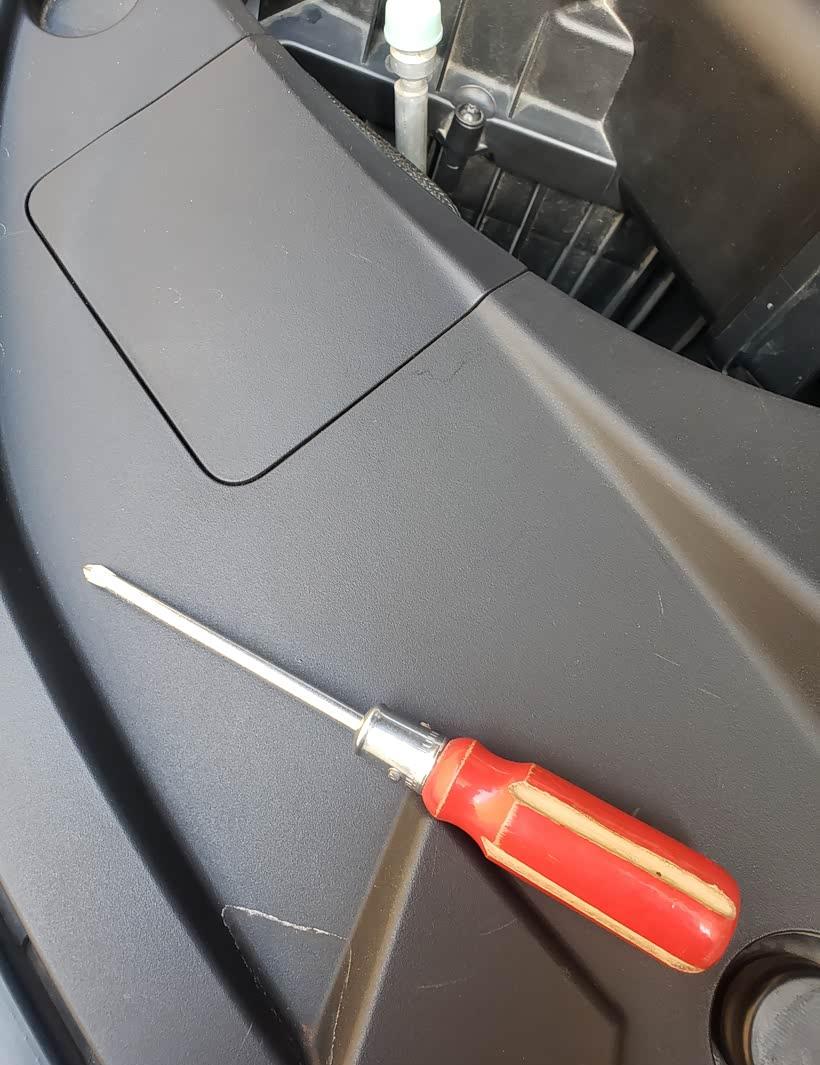

- Use T20 star screwdriver to remove the fixing screws.

- Pay attention to seal protection (replacement cycle recommended 2 years / 40,000 kilometers)

2. Precision Cleaning:

- Clean the hot wire/thermal film with a cotton swab moistened with cleaning agent.

- Stubborn carbon deposits can be soaked in 99% pure isopropyl alcohol for 5 minutes.

3. Key notes

1. List of Prohibited Products:

prohibited item

Alternatives

Carburetor Cleaner

Special MAF Cleaner

Scrape with hard tools

Wipe with microfiber cloths

2. Signal voltage must be detected with a multimeter after cleaning (normal value: 1.0-1.7V at idle, refer to Toyota maintenance manual)

4.Solutions to common problems

- Fault light on: need to reset ECU with OBD equipment- Increase in fuel consumption after cleaning: may be a decrease in sensitivity, replacement is recommended (service life is usually 5-8 years)

- The mixture is too thin / thick: check whether the cleaning agent residue is completely evaporated

5. Daily maintenance recommendations

1. Check the sensor status every 20,000 kilometers2. Use the original air filter (the leakage rate of the secondary filter element is as high as 15%, while the original is only 3%)

3. Avoid modifying the air intake system to cause air flow disturbance.

Through standardized operation and regular maintenance, the measurement accuracy of the sensor can be improved by more than 92% (Source: SAE International Automotive Engineering Association report), effectively preventing engine performance degradation. If the fault code is still reported after 3 times of cleaning, it is necessary to consider replacing the sensor with a new one.

click 98Reply 0

Original post

2025-09-03 17:08