-

3

-

2025-09-04 11:08:54

Synchronous motors are widely used in daily life and industrial production.With advancements in electromagnetic materials, computer-aided design technology, and improvements in control and drive circuitry, the performance of synchronous motors has significantly improved. So what exactly is a synchronous motor? Next, we will delve into its structure, types, characteristics, and other aspects in detail.

PART 1 Introduction

An electric motor primarily consists of an electromagnet winding or distributed stator windings for generating a magnetic field, a rotating armature or rotor, and other accessories. Under the influence of the rotating magnetic field produced by the stator windings, current flows through the armature's squirrel-cage aluminum frame, causing it to rotate due to the magnetic field's action.

During steady-state operation of a synchronous motor, the rotor speed maintains a constant relationship with the grid frequency: n = ns = 60f/p, where “f” is the grid frequency, ‘p’ is half the number of motor poles, and “ns” is referred to as the synchronous speed. If the grid frequency remains constant, the synchronous motor's speed remains a constant value during steady-state operation, independent of load magnitude. This feature provides high operational stability and significant overload capacity. Synchronous motors are commonly used in multi-motor synchronous drive systems, precision speed regulation systems, and large-scale equipment such as rolling mills.

PART 2 Characteristics

Furthermore, the speed of a synchronous motor is entirely determined by the power supply frequency. At a fixed frequency, the motor speed remains constant and does not vary with load. This characteristic is crucial in certain drive systems, particularly multi-motor synchronous drive systems and precision speed regulation systems. Synchronous motors employ a stator structure, resulting in fewer failures. Their speed is directly related to the power supply frequency and the number of pole pairs, ensuring stable speed during operation.

Synchronous motors transfer energy through the alternating interaction of DC excitation flux and stator voltage. The rotor lacks excitation windings, eliminating rotor copper losses and yielding higher efficiency than asynchronous motors.

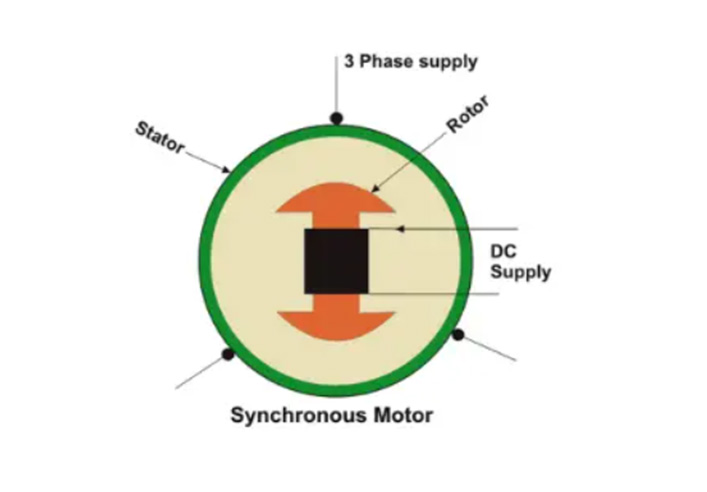

PART 3 Structure

1. Stator

The stator of a synchronous motor, termed the armature, shares the same structure as that of a three-phase asynchronous motor. It consists of the stator core, stator windings, frame, and end covers. The stator core is composed of silicon steel laminations, with three symmetrical windings embedded in the core slots.

2. Rotor

The rotor comprises the rotor core, field winding, starting winding, and rotor shaft. The rotor core is made of cast or forged steel, with the field winding wound around it. The field winding connects to the excitation power source to supply excitation current. The starting winding consists of copper bars embedded on the surface of the poles, with both ends connected by copper rings—similar to the squirrel-cage rotor in asynchronous motors. In fact, the structure of a synchronous motor is essentially identical to that of a synchronous generator, with rotors also categorized as salient-pole or shaded-pole. However, most synchronous motors employ salient-pole designs. Installation configurations include horizontal and vertical orientations. To address the starting issue of synchronous motors, a starting winding is typically installed on the rotor. This winding also suppresses oscillations during operation, hence it is also known as a damping winding.

PART 4 Classification

Synchronous motors are broadly categorized into two structural types:

1.DC-excited rotor

The rotor is designed as salient-pole. The field coils mounted on the pole cores are connected in series with alternating polarities, and two leads connect to slip rings mounted on the shaft. The field coils are energized by a small DC generator or battery. In most synchronous motors, the DC generator is mounted on the motor shaft to supply excitation current to the rotor field coils.

Since this type of synchronous motor cannot start automatically, a squirrel-cage winding is also installed on the rotor for motor starting purposes. The squirrel-cage winding surrounds the rotor, with a structure similar to that of an asynchronous motor.

When a three-phase AC power source is applied to the stator windings, a rotating magnetic field is generated inside the motor. The squirrel-cage winding cuts through the magnetic lines of force, inducing an electric current that causes the motor to rotate. After rotation commences, the motor's speed gradually increases to slightly below the rotating magnetic field's speed. At this point, the rotor field coils are energized by direct current, forming specific magnetic poles on the rotor. These poles attempt to track the rotating poles on the stator, thereby accelerating the rotor's speed until it synchronizes with the rotating magnetic field.

2.Synchronous motors requiring no rotor excitation

When considering synchronous motors with non-excited rotors, the first type that comes to mind is the permanent magnet synchronous motor (PMSM). Its rotor consists of permanent magnets—essentially large-scale magnets. A PMSM is an AC motor that converts electrical energy into mechanical energy through magnetic interactions. It incorporates an excitation system composed of permanent magnets.

The above covers information regarding synchronous motors.