-

43

-

2025-09-05 16:49:41

The ability of drones to fly relies on a set of interlocking propulsion logic: first, take electricity from the battery and convert it into mechanical energy that can turn the propeller, so as to drive the body to achieve high-speed flight. When the propeller rotates, it actively "pushes" the surrounding air - at this point, Newton's third law comes into play, the pushed air will not be "unresponsive", but will give the drone an upward lift.When the lift exceeds the weight of the drone itself, it can smoothly take off from the ground.

If you want a UAV to do complex moves—like turning or hovering—you don’t need some super complicated design. All you gotta do is adjust the speed of its different motors, and it’s actually pretty precise. But here’s the thing: how much power the motors have, and how efficient they are, directly affects how well the UAV flies and how long it can stay up in the air. That’s a total key factor for how well the UAV works overall. Now, when it comes to motor types, there are basically two main kinds: DC motors (yeah, just DC motors) and AC motors (same, AC motors). And DC motors can be split into two more types: brushed DC motors and brushless DC motors—most people just call those BLDC motors for short.

In the realm of unmanned aerial vehicles (UAVs), brushless DC motors (BLDC) predominantly prevail; only a limited number of cost-effective or toy-grade models may utilize brushed motor technology.

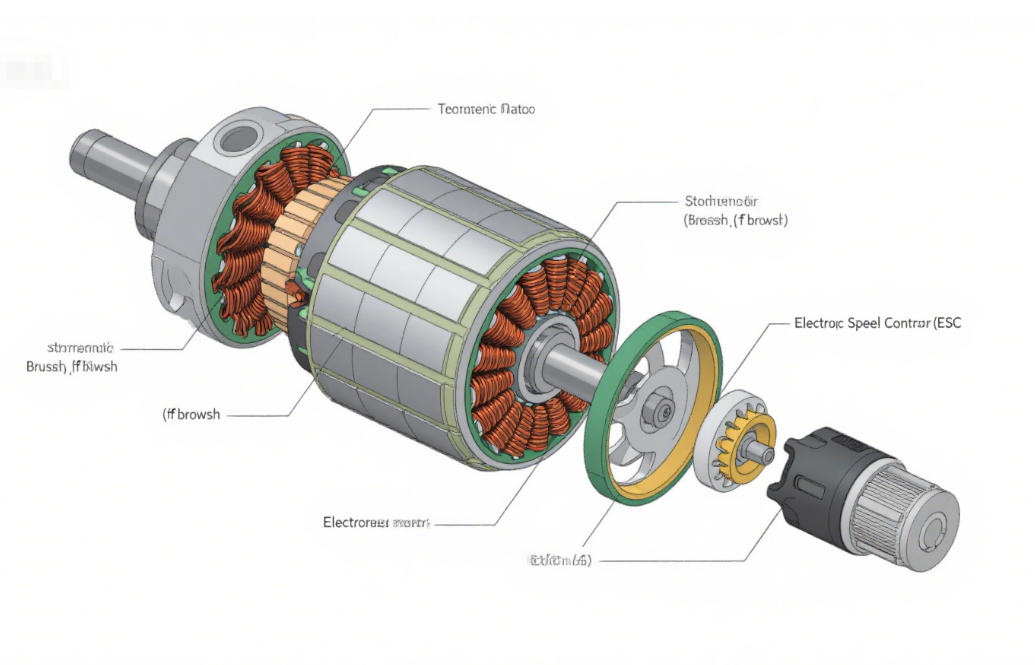

A brushed DC motor primarily comprises a magnetic pole stator (stationary), a coil rotor (capable of rotation), a commutator, and a pair of brushes—typically constructed from graphite—commonly referred to as carbon brushes. This type employs mechanical commutation: while both stator and brushes remain fixed in position, it is instead the rotor along with its commutator that rotates. The frictional interaction between these brushes and commutator induces periodic reversals in coil current direction, thereby facilitating continuous rotor rotation.

Advantages include simplicity in structure, affordability in production costs, and ease in control circuitry design.

Disadvantages entail lower efficiency levels coupled with reduced lifespan due to wear on brushes—particularly pronounced at elevated speeds—which are chiefly observed within micro toy drones.

Brushless DC motors (BLDC) mainly consist of permanent magnet rotors, multi-phase winding stators, and Hall effect position sensors (optional). Its working principle is based on electromagnetic induction and the interaction of magnetic fields: The stator contains multiple sets of coils (usually wound with insulated wires), which are fixed to the motor housing; The rotor is composed of permanent magnets and arranged in a specific number of magnetic pole pairs. Brushless motors must rely on an electronic speed controller (ESC) for control. The ESC converts the direct current from the battery into three-phase alternating current and precisely adjusts the motor speed according to the flight control instructions.

Advantages: High efficiency, long service life, low heat generation, high power density (strong power), and basically maintenance-free (no brush wear). Disadvantage: It relies on the matching electronic speed controller (ESC), which is relatively costly.

The hollow cup motor is a special type of DC motor, and its core feature is the adoption of a coreless rotor design. This structure endows it with significant advantages: high energy conversion efficiency, rapid response capability, excellent drag characteristics and high power density. Its efficiency usually significantly exceeds that of traditional iron core rotor motors (the latter are generally below 70%), generally exceeding 70%, and some models can even reach over 90%. Therefore, hollow cup motors are widely used in the field of model aircraft and unmanned aerial vehicles.

A servo motor is a highly integrated servo system that combines a DC motor, driver and encoder. Its core advantages lie in high integration, high-precision control, rapid response and high operational efficiency. This motor is widely used in tethered unmanned aerial vehicles (UAVs) and UAV gimbal control systems. In gimbal applications, servo motors can achieve precise attitude adjustment, significantly enhancing the stability and smoothness of the images captured by drones.

Key parameters of the motor

>> KV value

It refers to the rotational speed of the motor corresponding to a unit voltage under no-load conditions (unit: RPM/V). For example, a 1000KV motor operates at a theoretical speed of approximately 10,000 RPM at a voltage of 10V.

Low KV motor: Suitable for large-sized propellers (typical scenarios: long-endurance unmanned aerial vehicles, large aircraft models), with high torque output.

High KV motor: Suitable for small-sized propellers (typical scenario: racing drones), with high rotational speed but relatively low torque.

Size marking number

Expressed in four-digit numbers (such as 2205, 2306) :

First two: Stator diameter (unit: mm)

Last two: Stator core stack height/thickness (unit: mm)

Example: The 2306 motor corresponds to a diameter of 23mm and a height of 6mm.

Rule: Larger sizes usually offer higher torque and power, but with increased weight.

Power and efficiency

Power is jointly determined by voltage, current and KV value, and needs to be matched with the load characteristics of the propeller.

High-efficiency motors can significantly extend the battery life.

Differences in application scenarios

Consumer-grade drones (such as DJI) : They adopt customized brushless motors, with core demands: low noise and high energy efficiency.

Racing drones: High-KV motors are preferred to pursue instantaneous explosive power, with endurance being a secondary consideration.

Agricultural drones: Relying on high-torque motors to drive large propellers, core advantages: Enhanced payload capacity and wind resistance.

Frequently Asked Questions

Overheating: Potential causes → Motor overload, mismatch between KV value and load, ESC failure or poor heat dissipation.

Abnormal vibration: Inspection points → Motor shaft deformation, propeller dynamic balance failure.

Difficulty in starting up: Troubleshooting points → Abnormal ESC calibration, incorrect configuration of the electronic speed control communication protocol.

The selection of unmanned aerial vehicle (UAV) motors requires a comprehensive consideration of the model structure, load capacity, endurance requirements, and flight mission objectives. Brushless motors have become the mainstream in the industry due to their high reliability. Among them, the KV value, the matching degree of motor size and propeller are the core factors for achieving performance optimization. In DIY assembly or maintenance scenarios, it is recommended to strictly refer to the thrust test data provided by the manufacturer (such as the "Motor-Propeller Matching Thrust Comparison Table") for selection and matching to ensure that the power system is in the best working condition.