-

21

-

2025-09-25 14:57:35

When driving, we can always easily use headlights, air conditioners, and central control screens, but have you ever wondered: Where does the electricity from these devices come from?In fact, except for the battery-powered power supply when starting up, most of the electricity in the car comes from an “invisible power plant”-the car generator.It is like the “energy heart” of a car, silently turning the kinetic energy of the engine into electrical energy to ensure the normal operation of the entire vehicle's electrical equipment.Today, we will use the most popular language to disassemble how it works.

Figure it out first: what is the “core task” of the generator?

First of all, we must clarify a misunderstanding: automobile batteries are not the "main power supply", but the "emergency reserve".When starting the car, the battery will release current to drive the starter and let the engine run; however, after the engine starts, the battery will "take a back seat” and the generator will take over two key tasks.:

First, it supplies power to the entire vehicle's electrical equipment, such as headlights, wipers, audio, car chargers, etc. The daily electricity consumption of these equipment depends on the generator to supply in real time.;

The second is to charge the battery and store the excess electrical energy to avoid the battery losing power the next time it starts.Simply put, the core of the generator is “power generation + power replenishment” to ensure that the automobile power system does not “power off”.

Dismantling the generator: 3 key components, not one less

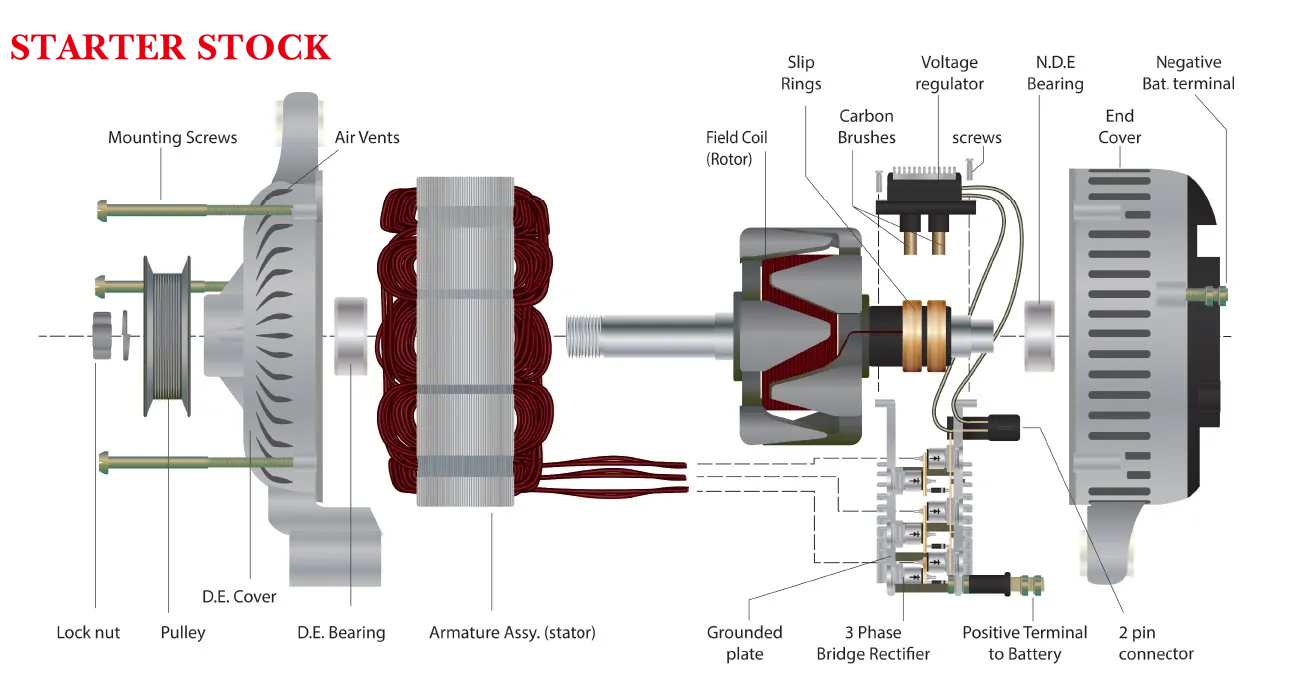

The generator looks like a small metal box, but the internal structure is very delicate. The core relies on three components: stator, rotor, and rectifier. We can think of them as the “three brothers of power generation”, with a clear division of labor and mutual cooperation.

1. Rotor: "Magnetic field maker”

The rotor is like the “magnet core” of a generator, and its task is to create a magnetic field.You can understand it as an "electromagnet”: it consists of an iron core and a coil wound on the iron core, and both ends of the coil are connected to an external circuit.When current passes through the coil, the rotor generates a strong magnetic field, which is the “basic raw material” for power generation-without a magnetic field, electrical energy cannot be generated in the future.

And the rotor is not fixed, it will rotate with the engine.Because the generator is connected to the engine crankshaft through a belt, as long as the engine is turning (even at idle speed), the rotor will rotate at high speed, and the magnetic field will “move” with it.

2. Stator: "Electrical energy producer”

The stator is the “main force of power generation” of the generator. It is fixed in the generator housing and surrounds the rotor, just like a ”coil network surrounded by a magnetic field."The stator consists of three independent sets of coils (called “three-phase windings”), and there are terminals at both ends of each set of coils.

A simple physical principle is used here: a conductor cutting a magnetic induction wire will generate an electric current.When the rotor rotates at high speed with a magnetic field, the coil of the stator will continue to “cut” the magnetic induction line generated by the rotor, just like using a wire to quickly cross a magnet.At this time, alternating current will be generated in the three sets of coils of the stator-this is the electrical energy originally generated by the generator.

However, the electrical equipment in the car (such as headlights and central control) requires direct current, and the alternating current cannot be used directly, which requires a third component to “take action.”

3. Rectifier: "Current converter”

The role of the rectifier is straightforward: it converts the alternating current generated by the stator into direct current that can be used by the car.It is like a "current filter", composed of 6 diodes (three groups, two in each group), the diode has a special property: only current is allowed to pass through in one direction.

When the stator outputs alternating current (the current direction will change repeatedly), the diode of the rectifier will “filter” the current: only the forward current is allowed to pass through, the reverse current is prevented, and the alternating current is turned into a single direction of direct current.After rectification, the direct current will be divided into two channels: one way directly supplies the entire vehicle's electrical equipment, and the other way flows to the battery to charge the battery.

There is also a "regulator”: to avoid power "overload”

In addition to the “three brothers of power generation”, there is also a key “regulator” in the generator-the voltage regulator.You may ask: If the engine speed becomes faster (such as stepping on the accelerator to accelerate) and the rotor turns faster, will the current generated by the stator become larger?The answer is yes.However, the voltage that automotive electrical equipment and batteries can withstand is fixed (for example, for 12V models, the voltage is usually stable between 13.5-14.5V). If the voltage is too high, the equipment will be burned out; if the voltage is too low, it will not be able to supply power and charge normally.

The role of the voltage regulator is to “stabilize the voltage”: it will monitor the voltage output of the generator in real time. When the voltage is too high, it will reduce the current flowing to the rotor coil, weakening the magnetic field of the rotor, thereby reducing the voltage generated by the stator; when the voltage is too low, it will increase the current flowing to the rotor coil, making the magnetic field stronger and increasing the voltage generated by the stator.Through this "real-time adjustment", it is ensured that the voltage output by the generator is always stable within the appropriate range, and it will neither be overloaded nor under-powered.

Summary: The “workflow" of the generator is actually very simple

Stringing together the above components and principles, the working process of the generator can be summarized into 4 steps, just like an "energy conversion assembly line”:

1. Power transmission: When the engine is running, the generator rotor is driven to rotate by a belt;

2. Magnetic field generation: The voltage regulator energizes the rotor coil, and the rotor generates a rotating magnetic field;

3. AC power generation: The rotating magnetic field cuts the stator coil, and the stator generates alternating current;

4. Rectifier power supply: The rectifier converts alternating current into direct current, part of which is used by the whole vehicle equipment, and part of which is used to charge the battery. At the same time, the voltage regulator stabilizes the voltage in real time.

The whole process starts from the engine starting to the end of the engine turning off, and the whole process runs automatically. We don't need to operate manually when we drive-this is the secret of the “invisible work” of the car generator.

Reminder: How to protect the generator?

Although the generator is durable, care should be taken to maintain it in daily use to avoid early damage.:

1. Do not use electrical equipment (such as turning on the headlights and listening to the audio) for a long time after the engine is turned off, otherwise the battery will lose power and the load on the generator may be increased the next time it starts.;

2. Regularly check the tightness of the generator belt: if the belt is too loose, it will slip, causing the generator speed to be insufficient and unable to generate electricity normally; if it is too tight, the belt and generator bearings will be worn out.;

3. If you find that the brightness of the headlights is flickering and dim, and the battery light on the dashboard is on, it may be that there is a problem with the generator or regulator. It is necessary to repair it in time to avoid power failure halfway.

In fact, the principle of an automobile generator is not complicated. The core is “the kinetic energy is turned into electricity, and then the electrical energy is turned into electricity for energy use.”The next time you drive, when you turn on the headlights or air conditioner, think about it: behind this is the generator rotating at high speed, silently completing the energy conversion-it is this small “invisible power plant” that makes our driving life more convenient and safer.