-

66

-

2025-08-01 10:37:48

1. Working Principle of a Starter Motor

1.1 Basic Electromagnetic Principles

1.2 Starter Motor Characteristics

1.3 Complete Operation Process

2. Key Design Points for Starter Motors

2.1 Design Input: Clarify Starting Requirements

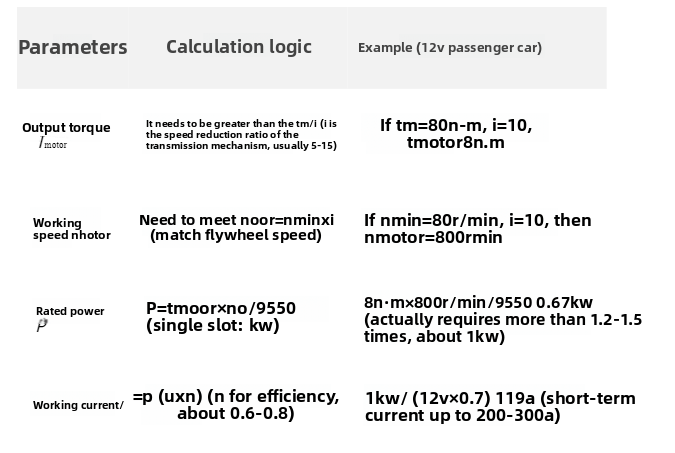

2.2 Core Parameter Design

mportant;"> Based on the input requirements, calculate the key parameters of the motor:

mportant;">

2.3 Design of Key Components

(1) DC Motor Design

(2) Transmission Mechanism Design

(3) Control Device Design

2.4 Reliability and Environmental Adaptability Design

click 66Reply 0

Original post

2025-08-01 10:37