Product Description

The 88SSTE series motors are designed to meet stringent industrial application standards and are highly suitable for heavy industrial applications that require precise power control, such as large automation systems, industrial robotic arms, or heavy processing equipment. Its circular design and robust construction ensure long-lasting reliability in high load and complex operating environments, making it an ideal choice for applications that require extremely high power and durability.

baolong supply offer motor three aspects related to the functioning and control of servo motors.

Servomotor Encoder: A servomotor encoder is a device used in servo motor systems to provide feedback on the motor's position, speed, and direction. The encoder is typically attached to the motor's shaft and generates electrical signals that are used by the motor controller to precisely control the motor's movement. By continuously monitoring the encoder signals, the controller can make adjustments and maintain accurate positioning of the motor shaft.

In general, a servo motor arm could refer to the mechanical component or linkage attached to the servo motor shaft that connects and actuates other parts of a system.

Servo Motor Closed Loop: Servo motors commonly operate in closed-loop control systems. servo motor closed loop system uses feedback from sensors, such as encoders, to continuously monitor and adjust the motor's position, speed, and torque. The feedback signals are compared with the desired values, and any discrepancies are used to generate control signals that adjust the motor's operation. This closed-loop control mechanism enables precise and accurate control of the servo motor's position and movement.

The combination of a servomotor encoder, servo motor arm, and servo motor closed loop control forms the basis for achieving accurate and controlled motion in servo motor systems. The encoder provides feedback on position and speed, the motor arm translates the motor's rotational motion into desired mechanical movement, and the closed-loop control ensures the motor's performance aligns with the desired parameters.

Electrical Specifications

| Motor Model | 88SSTE485030 | 88SSTE2205030 | 88SSTE2207530 |

| Number of Phase | 3 | 3 | |

| Number of Poles | 8 | 8 | |

| Rated Voltage(VDC) | 48 | 220 | |

| Rated Speed(Rpm) | 3000 | 3000 | |

| Rated Torque(N.m) | 1.6 | 1.6 | 2.39 |

| Rated Power(W) | 500 | 500 | 750 |

| Rated Current(A) | 14 | 3.3 | 5 |

| Peak Current(A) | 42 | 10 | 15 |

| Peak Torque(N.M) | 4.8 | 4.8 | 7.1 |

| Rotor Inertia(kg.cm2) | 1.6 | 1.6 | 2.1 |

| Torque Constant(N.m/A) | 0.11 | 0.51 | 0.51 |

| Torque Constant(V/krpm) | 10.47 | 40 | 42 |

| Line-Line Resistance(Ω) | 1 | 3 | 2.2 |

| Line-Line Inductance(mH) | 0.9 | 6 | 9 |

| Length(mm) | 95 | 95 | 115 |

| Weight(kg) | 2.04 | 2.2 | 3.2 |

| Encoder Resolution(P/R) | 1000,1024,2500/17bit,23bit | ||

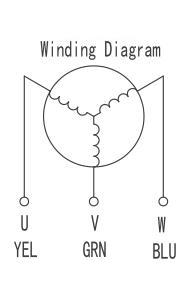

Wiring Diagram

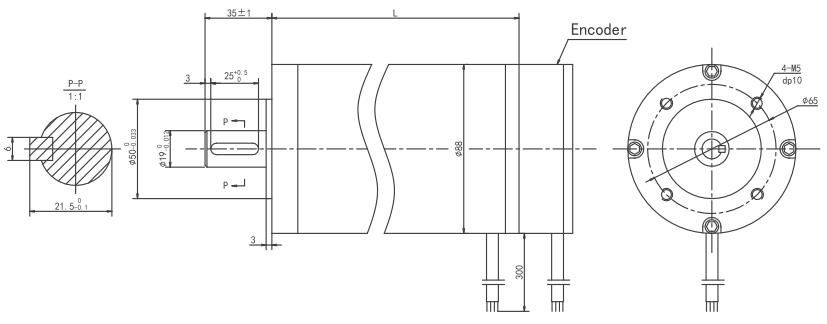

Dimensions(Unit: mm)

1 years

China

1 years

China