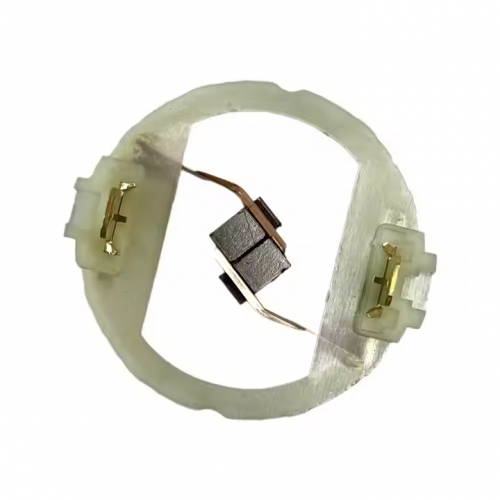

Replacement Parts: 895, 875, 887 Motor Carbon Brush Holder for Cordless Screwdrivers, Wrenches, and Drills

1. Product Identification

Part Type: Motor carbon brush holder (a component that houses and secures carbon brushes in the motor).

Model Numbers: 895, 875, 887 (likely unique identifiers for specific holder designs or compatible tool series).

Application: Replacement part for cordless power tools, including screwdrivers, wrenches, and drills.

2. Core Function

Holds & Aligns Brushes: Secures carbon brushes in precise position within the tool’s motor, ensuring consistent contact with the commutator (critical for electrical current transmission).

Maintains Pressure: Integrates springs to apply steady pressure (1.2–1.8kg) on brushes, compensating for wear and preventing sparking—even under the vibration of cordless tool operation.

Insulates & Protects: Acts as an insulating barrier between the conductive brushes and the tool’s metal motor housing, reducing short-circuit risks.

3. Compatible Tools

Designed for cordless (battery-powered) tools such as:

Cordless screwdrivers (low-torque, precision applications).

Cordless wrenches (high-torque, for fastening/loosening bolts).

Cordless drills (versatile for drilling and driving).

The model numbers (895, 875, 887) indicate compatibility with specific tool series—verify with your tool’s brand and model to ensure fit.

4. Key Features

Material: Lightweight, heat-resistant plastic (e.g., ABS or nylon with glass fiber reinforcement) to withstand battery motor temperatures (up to 100°C) and resist impact from tool use.

Design: Compact to fit the smaller motor housings of cordless tools, with precise slots for brush insertion and secure mounting points.

Durability: Engineered to handle the repetitive motion and vibration of screwdriving, wrenching, or drilling without cracking or losing structural integrity.

5. Replacement Indicators

Physical damage (cracks, broken tabs, or warping) that disrupts brush alignment.

Spring failure (loss of tension) leading to poor brush-commutator contact, resulting in weak tool performance, intermittent operation, or sparking.

Wear or corrosion on internal surfaces that hinders smooth brush movement.

6. Installation Notes

Must be compatible with the tool’s motor size and brush dimensions to ensure proper fit.

When replacing, check that the new holder’s spring tension matches the original (1.2–1.8kg) to avoid uneven commutator wear.

Should be replaced alongside worn carbon brushes for optimal motor performance.

7. Importance in Cordless Tools

Enables reliable current flow from the battery to the motor, directly impacting tool power (torque, speed).

Protects sensitive battery motor components (commutator, rotor) from damage due to misaligned brushes.

Ensures consistent operation in cordless tools, where efficient power transfer is critical for battery life.

1 years

China

1 years

China